Description

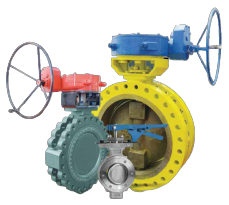

Valvtron Titan Severe Service Ball Valve

For the most abrasive applications and High temperatures

All these components have been designed to ensure extended trouble-free service.

BODY

• Forged material

• Rigid Actuator Mounting Pad

• End connections to suit Customer Piping

• Non-Standard face to face dimensions easily accommodated

SEAT END

• Integral seat. No possibility of particles behind the seat

• Large range of Hard Facing materials to suit most applications

• HVOF coatings have high Bond strength

• Excellent Thermal expansion Capability

• Non-Porous up to 5 times harder than Stellite 6

• Low Coefficient of friction

STEM

• Large section heavy-duty stem

• Design ensures no side loads

• Torsion-resistant materials

• Hardened for long leak-free service

• Same stem & ball center lines prevents camming & side loads

BALL

• Hardened, ground & lapped to achieve tight shut-off(Zero Leakage)

• Large diameter with the full port as standard

• Large diameter also allows full-depth stem engagement

BALL GUIDE

• Hardened & lapped to ensure the long service life

• Static Spring force once assembled

• Body seat & guide hard coated & lapped to the same standard

• Ensures precise ball-to-seat alignment at all times

SPRING

• Manufactured from a material suitable for temperatures up to 600ºC

• Deflected to obtain the desired seating force on the assembly

• Ensures that Ball & Seat are always in seating contact

• Static spring force in normal conditions

• Can allow for unexpected thermal expansion

BODY GASKET

• All metal body gasket spiral wound

• Self energized

• Pressure seal

• Re-usable

• Fire Resistant

• Optional leak detection port and secondary gasket

GLAND FLANGE

• Precision machined and hardened to provide additional stem support

• Optional Live-loading ensures compliance with fugitive emission requirements.

GLAND PACKING

• Graphite or Graphoil rings with anti-extrusion bull rings

• Optional Lantern ring & Leak Detection Port

• No Side loads

• Precision machined stuffing box & hardened and polished stem.

SEATING MATERIALS

The following choices are available

Chromium Carbide

• Hardness 1100 Vickers

• Cr Carbide Ni-Chrome Matrix

• Good Corrosion resistance and suitable for temperatures up to 600ºC

Suitable for

• HP Steam and Condensate (Flashing) Boiler Download

• Catalyst withdrawal

Tungsten Carbide

• Hardness 1300 Vickers

• Excellent abrasion resistance

• Good corrosion resistance

• Temperatures up to 450ºC

Suitable for

• Hydrocarbons

• Flyash

• Severe abrasion – heavy metals etc

Alumina Ceramic

• Hardness 1300 Vickers

• Chemically Inert up to 2000C

• Non-Permeable

• Good wear resistance

Suitable for

• Corrosive and acidic Mining Slurries

Amorphous Metal Alloy

• Hardness 1400 Vickers

• Maximum Abrasion resistance

• Maximum Corrosion resistance

• Low Coefficient of friction

• Suitable up to 450ºC

Valvtron Titan Severe Service Ball Valve

Suitable for Chemical Slurries