Description

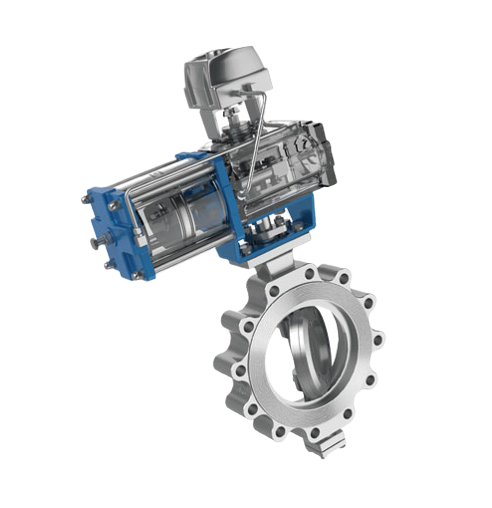

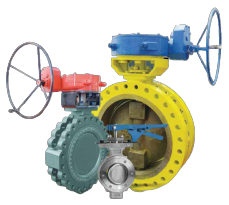

Triple Eccentric Butterfly Valve

The triple offset design incorporates torques in seating for tight shutoff or control even in the roughest applications. Industries, where the triple offset butterfly valves are widely used, include Power, Refining, Petrochemical, Chemical Pulp, and Paper.

Features:

Shaft Bearings

The shaft is centered on two self-lubricating bearings with extremely high rotation precision and stability. Bearing is PTFE lined on the internal surface on bronze-centered stainless steel base material with super abrasion resistance and self-lubrication to free from seizure problems.

Compact Construction

Due to the nature of their design, butterfly valves can offer very short face-to-face dimensions. Less metal means butterflies are often a very economical alternative to ball valves. Also, reduced torque for butterfly valves offers, even more, cost savings, as they can be operated with smaller actuators.

Low Emission Shaft

Shafts are precisely ground by a CNC machine with a very fine finish and low friction factor, therefore, low emission from packing and long packing cycle life.

Various Sealing Design

Valves come standard with a laminated disc seal and graphite layers carefully assembled between stainless steel layers with reliable high-temperature resistance and seat tightness. Toque seating during the closing of the valve provides friction-free sealing for long circle life. Based on the suitability of the intended service, seat options may include a PTFE seat, a metal seat. Consult Linuo with specifics on your application, and we’ll be happy to help to select a valve for your service.